Bristle materials

About the material, which bristles are made of

The versatility of our brush solutions is in the end based on the extensive variety of materials. And because the bristles of Mink brushes are doing the actual work, choosing them deserves particular attention. Here the selection criteria are also extremely varied. The criteria orientate most of all on the future function your brush. As a standard we manufacture our brushes with wire, plastic or natural bristles. For special applications also different combinations and a mix of different ratios of raw materials are possible. Also available; electrically conductive or flame retardant bristles.

Download the chart, which gives you an overview of all the different bristle materials and their properties. Moreover, our experienced advisors are always available to assist in choosing the right individual solution for you.

Properties of the brush bodies

Quality for a good reason

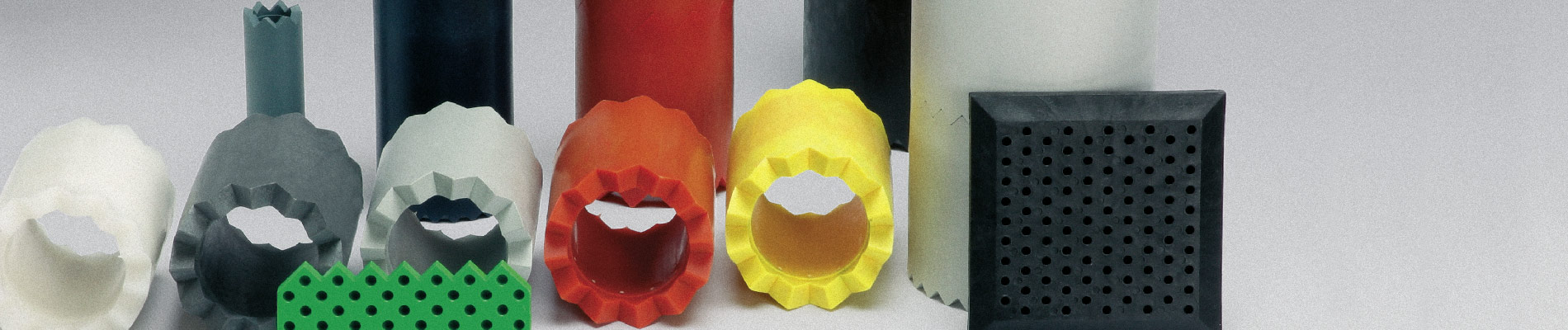

As the market leader in filament technology, we poses the unique know-how of punching bristles of carrier materials. In collaboration with our carefully selected reliable suppliers, we are offering brush bodies, which are customised to all your requirements. Check your mechanical, thermal, chemical and electro static conditions – Mink brushes will meet your requirements with the ideal brush body material. Naturally, special solutions are here also possible. We are happy to develop also plastic injection molded parts according to your specifications.

Download the chart, which gives you an overview of the brush body materials and their properties. Moreover, our experienced advisors are always available to assist in choosing the right individual solution for you.

Injection molded parts

Quality for a good reason

Mink Brushes is not only an idea generator for mechanical engineering, but also innovative when it comes down to being agile and economical. Thanks to our own modern injection molding department combined with our machining, bristle punching and R&D of extrusion profiles we are widely independent – therefore even better equipped to collaborate with our customers.

Extrusion profiles

Customised products for you

Mink brushes assist in developing extrusion profiles and offers the possibility to optimally adjust technical brushes to profile cross-sections as used in your application. Naturally, we take into account that the mounting is as straight forward as possible; for instance clip in, slide in or plug on. The necessary bristle for the desired function you may choose together with us from a multitude of options. Moreover, for all Mink standard profiles you may choose the colour to even create your own bespoke product.

Advice and customised special solutions

Questions to our products, prefer an individual solution for your application or would like to order a sample? We are pleased to offer you a high quality, guaranteed to succeed consultation. Kindly give us a few details so that we are able to find you the correct advisor. The more accurately you describe the problem, the better we can prepare for the callback.

Our specialist will contact you shortly. Alternatively, you can contact us by telephone or email:

Fon: +49 7161 4031-0

E-Mail: info@mink-buersten.de

On-site consultation visit?

Mink Brushes operates internationally and has advisors in several countries. Even though your company headquarters is not in Germany, there is most likely a possibility to arrange an on-site visit.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Polski

Polski